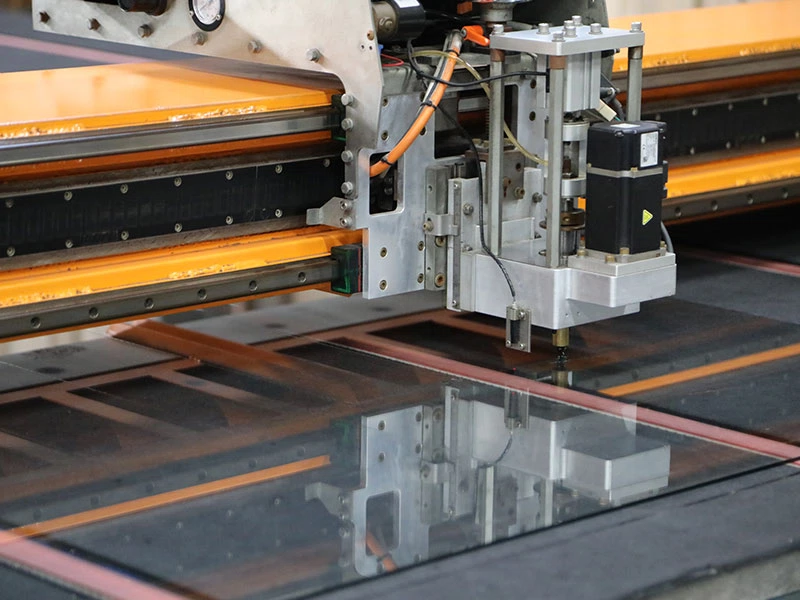

Glass CNC Cutting

Hony Glass Technology is equipped with multiple professional glass CNC cutting machines to meet the diverse needs of our customers. Our cutting services are fully customized according to the size, thickness, and shape of the glass substrate. With the design of multi-angle, high-hardness wheels, we precisely cut glass of different thicknesses, ensuring the accuracy and consistency of the cutting lines. Whether it is traditional straight-line cutting, standard circular cutting, or complex custom shapes, we provide the highest quality service according to customer requirements.

Our CNC cutting equipment not only handles high-complexity cutting tasks but also performs real-time quality monitoring at each step to ensure high precision and stability in our products. In addition, we utilize a CCD positioning system for precise alignment prior to cutting, enhancing the overall accuracy of the process. These advanced technologies not only optimize production efficiency but also ensure that every product meets the stringent quality expectations of our clients, often surpassing their standards.

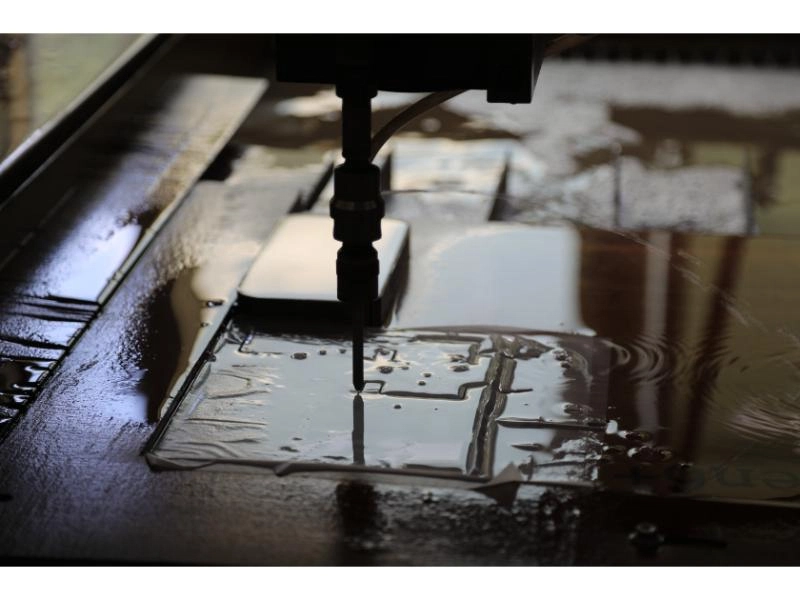

Waterjet Cutting

Glass waterjet cutting is a precise cutting technology that uses high-pressure water mixed with abrasive materials to create a powerful waterjet stream for cutting. This technology is suitable for glass with a thickness of over 6mm and can maintain smooth cutting edges while effectively avoiding breakage caused by thermal stress. Compared to traditional cutting methods, waterjet cutting offers higher precision and prevents deformation due to heat during the cutting process, ensuring the structural integrity of the glass.

Waterjet cutting is not only suitable for standard straight-line or circular cuts but can also handle a variety of complex glass shapes, accurately cutting fine details and irregular contours. Additionally, water jet cutting is ideal for both high-volume production and customized small-batch glass processing, demonstrating exceptional flexibility and efficiency.

Glass Laser Cutting

Our laser glass cutting service can handle glass thicknesses ranging from 0.1 mm to 19 mm. As a non-contact processing technology, laser cutting effectively avoids the introduction of additional mechanical stress during the cutting process, thereby preventing cracks and deformation in the glass.

Our high-precision laser cutting technology not only meets the diverse market demands for high-performance glass, but also supports complex shape cutting, we are also capable of processing convex and spherical glass, enabling precise machining of various non-flat structures with smooth edges and consistent dimensions. This ensures enhanced structural integrity and optical quality. We are committed to providing customers with stable and accurate processing solutions, ensuring that each product delivers exceptional performance and reliable quality.